Proper Sharpening Angles

I get asked all the time what the proper angle to sharpen a knife is. There is no one perfect angle for all applications, just like a mechanic doesn’t use a one-size-fits-all wrench to work on your car. Anyone with experience with knives, axes, and other tools sharpen each tool based on several different factors. If I was going to go with a one-size-fits-all approach to sharpening I would recommend you starting around 22 degrees (most knives are sharpened on both sides so that is a overall 44 degree edge). This is a good starting point that has been recommended for years.

Confession to Make

Although I have thrown around numbers like many others about angles to use, I have only recently actually measured the angles at which I sharpen my knives. Up until now I simply experimented with different angles. I like to push the knives and steels to their limits of cutting performance by using as low of an angle as possible.

If you go with too low of an angle, you may find that an edge is rolling over, chipping or just not holding up as long as you would like. If it were me, I would bring that edge up (increase the angle of the bevel) ever so slightly until I got to where I was happy with the performance for the particular knife and steel. When sharpening by hand there really isn’t a good way to measure the angle at which you are sharpening (there are some good ways to get a baseline). So it is more about practice and experience.

Three Determining Factors for Proper Sharpening Angles

Three main factors that determine the proper sharpening angles. They are

- Type/ Purpose of the Knife

- The Steel

- The User

Type/ Purpose of the knife-

It goes without saying that a razor for shaving will not split steel well and a cold chisel is no tool for shaving either. If you attempted either, you would end up greatly disappointed in the performance of the tools. Each of these examples are the two extremes of the spectrum. Just like you don’t expect a cold chisel to shave you shouldn’t expect a chef’s knife to be a survival knife.

I am sure you all have seen videos out there of knives chopping through chain, or puncturing metal barrels. As a young man I still remember watching the slick salesman selling the knives that would never get dull, performing some spectular feat to sell his knives. Many of which were really just junk knives, designed with a WOW factor to sell them. I can make a knife that is a great cold chisel as well but in the end most customers would end up greatly disappointed with the performance of the everyday task that isn’t cutting chains in half. Most things in life have trade-offs, a drag car may be able to reach top speeds in just seconds would make a horrible vehicle to take on a long road trip where fuel economy is important. Cutting tools are no different.

The Steel-

I started working with steel in High School when I first learned about welding. I can still remember the blinding arc of the welder and being amazed that you could hold in your hands the power to melt steel and bind it together to build things from steel. I knew that I wanted to learn how to work with steel as well, and over the last 20+ years I have done just that. Little did I know at that time that there are hundreds of different steels and rods, each having different properties for different applications. One steel may provide better corrosion resistance, but not without a cost. Just like the example of the drag car verses the economy, performance is sacrificed to provide better corrosion resistance. There is no perfect steel, and the craftsman must know the best steel for the application.

So what does that have to do with sharpening angles? Simply, some steels can take a real keen edge and can take and the stress of a nice shallow sharpening angle. Others are softer and require a steeper sharpening angle to hold up to the stress. If you have a steel that can handle the stress of a nice shallow sharpening angle, then use it. Knives are designed to cut, like that dragster is made for racing. It would be a shame to never take advantage of the performance it was designed for.

The User-

The last factor in determining the best sharpening angle is the user. We all know someone who can destroy an anvil in a sandbox. That is the guy that we have to take into consideration when sharpening knives. I have certain customers who I sharpen their knives based on this fact alone. I have to build them a tank because they are not going to take care of it at all.

I can still remember sharpening one guy’s knife only to find him scraping the gasket off of some steel not 5 minutes later. He had completely ruined that edge that I had just spent so much time making perfect. I did tell him that I would no longer spend time sharpening his knives if he was not going to take care of them. There is a right tool for every job and I can understand having to make due with what you have. However in this case it was a simple lack of care to get the right tool for the job.

Proper Angle

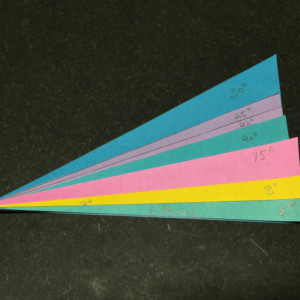

In conclusion, I really haven’t’ discussed sharpening angles in detail for a reason. I can give you guide lines of “oh where to start”. But only with practice, and experience can you really learn what angles are best for your knife, your steel, and you the user. If you would like to know the angles I suggest, I have included a baseline in the video below for the different cutting edges. You can see first hand the difference a few degrees make. I sharpened 3 Genesis II at 3 different angles: 15, 19, and 25 degrees. If you would like to learn more about sharpening, I cover all the steps I personally use myself to achieve what many customers and collectors have said to be the sharpest knife they own! Get your DVD of Beyond Razor Sharp Here.