CTS™-XHP VS EVERYONE ELSE! (By the data!)

Welcome back. In some ways, this is the hardest of the three posts about CTS™-XHP. In others… easy day. What I wanted to look at here was just a side by side comparison of a few different types of steels and then draw a conclusion or two. Basically, it’s a versus post! Who has the best stats? Let’s find out.

MTKnives is a little… different.

This post is going to approach this subject a little differently than most knife makers approach the subject. A lot of people in this industry like to take one knife and compare it to another using the rope-cut method. There are others but this one is pretty ubiquitous. Basically, you take a knife and sharpen it the same as another and see how many times you can cut through rope or some other object. Seems pretty simple on the surface. The knife with the most cuts wins. For the most part, this is a pretty awesome way to gauge the usefulness of a knife. However, part of it as always bothered me.

Reproducibility.

When scientists set out to make a discovery they conduct experiments. On the surface, the cut method seems like a pretty good experiment. But I think, scientists would cringe at all of the unaccounted for variables. Were the knives sharpened at the same angle with the same polish? Was the same part of the cutting edge used every time? Were the muscles of the people making the cuts on both knives using the same pressure? How much pressure constituted “loss of cutting ability?” Who decides when to call it quits? Were the judges objective (or did they want a particular knife to win so they could make more sales)? Was the item used a good metric to use or is there a more consistent material to use? Was the same item manufacturer used? Was the item used of the same quality as another? Did humidity play a factor? And on and on and on?

Here’s the point:

If I can’t reproduce your experiment and get the same results your experiment is qualitative at best. At worst, it is totally invalid! Don’t misunderstand what I am saying. I am not condemning a cutting test. It is awesome to watch a knife perform cut after cut and not get dull. Just don’t use it as hard scientific proof that a certain blade is better or worse. There is just too many variables. I plan on doing a video soon, and hopefully removing most of the variables I can.

Remove the variables.

The only way to decide that is to set up a lab and remove all possible variables from the equation except cutting edge performance. There can be no variation in any other factor of the test except cutting edge performance. If anything else changes it makes the experiment less reliable. You may still be able to use the results but only qualitatively.

With that out of the way, lets look at the basics.

There are a lot of things we could look at to determine what makes a metal the best for knives. We could look at all sorts of facts, figures, data, and information like:

- Corrosion Resistance

- Specific Gravity

- Density

- Coefficient of Thermal Expansion

- Compressive Yield Strength

- Compressive Modulus

- Tensile Yield Strength

- Ultimate Tensile Strength

- Elongation

- Reduction in Area

- Hardness BHN

- Hardness HRC

- Average ASTM Volume Loss

And about a million other things! Seriously, the ways we can describe metal is practically endless! Most scientist would settle for these three descriptions of a metal to assess it’s capabilities: hardness, strength, and toughness. We use these three words interchangeably at times, but in the world of metallurgy, they mean very different things.

Hardness

The materials ability to withstand friction. A diamond is very hard. One of the hardest materials in known to man. Being hard means that the material doesn’t scratch very easily. You can’t scratch a diamond. If a metal is very hard it will resist abrasion. It will also hold a sharp edge for a long time. But that is only part of the story.

Strength

The amount of force necessary for a material to deform. The harder it is to deform a material the stronger it is. Steel is very hard to deform and is therefore very strong. Silly putty is laughably easy to deform. It is not strong. If a steel is not very strong (relative to other steels) the edge will curl over faster. This deformation of the edge will reduce the sharpness of the knife.

Toughness

The material can resist fracturing when force (like the striking of a hammer) is applied. Inside the umbrella of toughness is a property called ductility. Which measures how much deformation a material will go through before fracturing. Diamonds are not tough. You can smash them with a hammer. Silly putty on the other hand, very tough. It doesn’t fracture, regardless of how hard you strike it!

Alright already tell me what the best knife steel in the world is!

Bringing it home

Steel is known for its strength. Some steel is harder than others. Some steel is tougher than others. But they are all known for being strong. As a knife maker, I am interested in edge retention and toughness. I want my knife to sharp for a long time and I don’t want it to be so brittle that it shatters anytime there is any force put on it like a glass knife would be. To gauge edge retention I am going to look at a combination of hardness and strength. Ok. Enough about that.

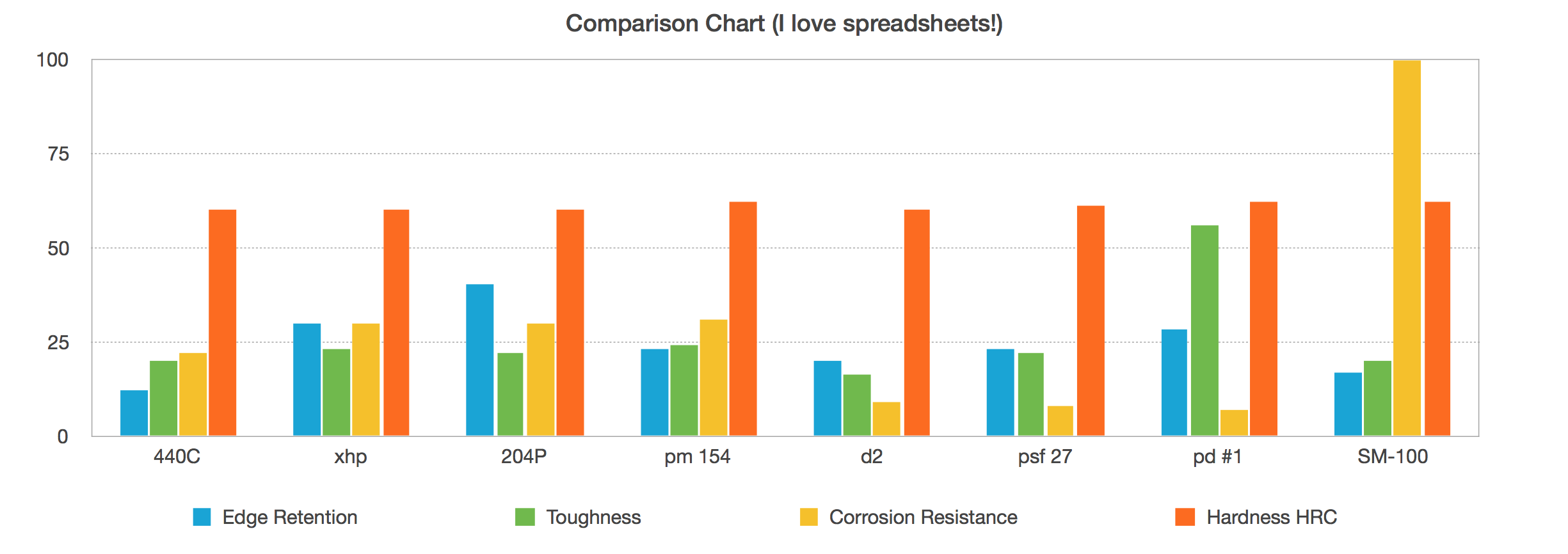

I took the data sheets of a few types of steels that I am interested in researching and that are known for being good knife steels. You will notice that I left a few out. Frankly, there a million types of steel out there and I was a bit choosy. There is a lot of data to sort through to make this kind of comparison. For the purpose of this comparison, I went right to the manufacturers’ data sheets. Like this one, or like this one. Without further ado. Here is what I found:

CTS™-XHP versus… other knife and cutlery steels.

44C, 204P, PM 154, D2, PSF 27, PD #1, SM #100

So what does it all mean?

Scientifically CTS™-XHP outperforms all other steels except CTS™-204P (which I have some future plans for). CTS™-XHP is very corrosion resistant for such a high carbon content (usually the higher the HRC the worse the corrosion resistance). CTS™-XHP might be a little tougher than its nearest competitor.

I like CTS™-XHP… That’s pretty much it.

It is one of the best steels on the market to make knives out of. Warning, I am about to get altruistic. I believe the quality of the knife is a reflection of the quality of the knife-maker, not a function of how many times a knife will cut a rope. Let me say that differently with a story.

The tale of two knife makers:

Two knife makers set out to make a knife. They used the same steel (Let’s just say it was CTS™-XHP). They used the same tools. They used the same blade design. They used the same handle material. In fact, they made them in the same shop. Would the two knives be equal? Of course not. One knife maker would make a superior knife. If one knife maker approaches the bench with the idea that he is just making another knife to sell, he will surely succeed. If the other knife maker approaches the bench with… heart, the knife will blow the other out of the water. This is why the Patriot won the super bowl with the biggest comeback in history. This is why Phelps is the best swimmer to have ever lived. When the knife maker has quality in his heart he will have quality in his knife.

Bottom Line

I like working with CTS™-XHP. It is a high performing knife steel. There isn’t much that compares. That said, I am committed putting the quality of my heart into the quality of my knives.

Amazon Item of the Week

Cut Resistant Gloves,Level 5 These gloves are a great ideal when using one of my knives 😀 Spring is coming and that means lots of working in the garden and hopefully some fishing. I can think of plenty of uses for these gloves, and if they save one trip to the ER they more than pay for themselves! Best part is by clicking the link below or Here you help support MT Knives by shopping on Amazon like I am sure you already do. Let me just say Thank You for your support!

very informative, thanks for the education…

Your most recent XHP write up certainly places XHP behind only 204P, one exception being the corrosion resistance of SM-100.

I was a little surprised to review the data set revealing that 440C was down on edge retention.

440C [on your chart] has the lowest edge retention value of any selected test subject. Interesting.

Your efforts are appreciated.

Carry on.